What is 3D Scanning

Additive manufacturing is actively used in modeling, design and construction. 3D scanning technology helps solve almost impossible tasks, simplifying the work of designers, architects and cinematographers. The high accuracy of reading the product’s surface and obtaining data on the size, configuration, and color of the object allows you to reproduce it in detail on a computer screen.

Digitization of a physical sample is an integral part of the manufacturing industry. The procedure of converting an object into an exact 3D model helps to form a computer copy. Scanning is implemented using unique markers that help fix the part’s dimensions and geometry. The resulting image can be used to perform complex measurements, adjust the configuration, form a CAD model, and launch into production.

The primary purpose of 3D scanning is parameter control and reverse engineering, where high measurement accuracy and speed of digital object creation are fundamentally important. When it is necessary to reproduce the product in a modified form, reverse engineering solves the problem. Based on the scan data, a computer model is built and finalized, which is subsequently sent to production.

What to do if you need 3D scanning

Many people try to do 3D scanning on their own, but due to low-quality equipment and a lack of knowledge, it is impossible to get a high-quality result. Therefore, many entrust the 3D scanning process to companies.

CyberFox has qualified personnel. Contact us and tell us about your task. Our specialists will be happy to help you with any questions.

Benefits of using CyberFox 3D scanning

CyberFox makes 3D scanning models based on drawings, sketches, and photographs. We help implement any project, from modeling parts for production to making a souvenir product model. Use the callback order service, and we will tell you the deadline for completing the order and the cost of 3D modeling.

Punctuality

We give you a realistic assessment of the work completion time. You always get the job right on time.

Flexibility

Based on your project, we will suggest how to achieve the best result. Just send the materials you have.

Knowledge

Our experience and knowledge allow us to offer the best solutions to show your ideas. If you have questions, just ask.

Speed

We perfectly understand when you need visualizations urgently. We work fast.

Experience

We share our expert opinion on how best to present your project because we care.

Saving time

You do not need to understand the software or 3D imaging technology. Everything is available at CyberFox.

Read on to get a brief overview of 3D scanning.

What is 3D scanning?

3D scanning is a technology for converting a physical object into a digital format, which significantly optimizes the process of measuring and manufacturing products. The result of the scan is a three-dimensional point cloud in .stl, .3d, .pol, or .play format.

What things can be 3D scanned?

How large can objects be and still be scanned with a short-range 3D scanner? For example, if the scanner has a measuring area of 500 x 500 mm, then it will be able to scan objects of that size.

To significantly increase the accuracy of measurement on large objects and ensure the quality of the result, you can use a photogrammetric system based on a manual digital camera.

Objects: The most popular application of 3D scanning. Using a 3D scanner, you can get a model of any part.

Living Beings: Using a 3D scanner, you can get models of the human body or animals. This method is used in medicine.

Surroundings: 3D scanning has become widespread for scanning location. This method is used to create models in architecture.

Advantages of using 3D scanning

Let’s consider the main advantages of 3D scanning:

Accuracy. The scanner has a small measurement area that provides the desired accuracy specified in the initial calibration. However, the 3D scanner has to be rearranged or moved when scanning large objects, which frequently results in errors. A photogrammetry system based on a hand-held camera is configured for a much larger field of view. In addition, the accuracy of determining each point on the surface is relatively high due to the high frame rate

Speed. When scanning a large object with a 3D scanner alone, a lot of time is spent on the alignment stage. However, suppose the coordinates of all the points are known in advance. Then, all the scanning data is immediately linked to the coordinates measured before by the photogrammetry system.

Simplicity. Scanning an object by points with known coordinates is much easier. You can check them at any time and in any place.

What are 3D scanning technologies?

Let’s consider what main types of 3D scanning exist:

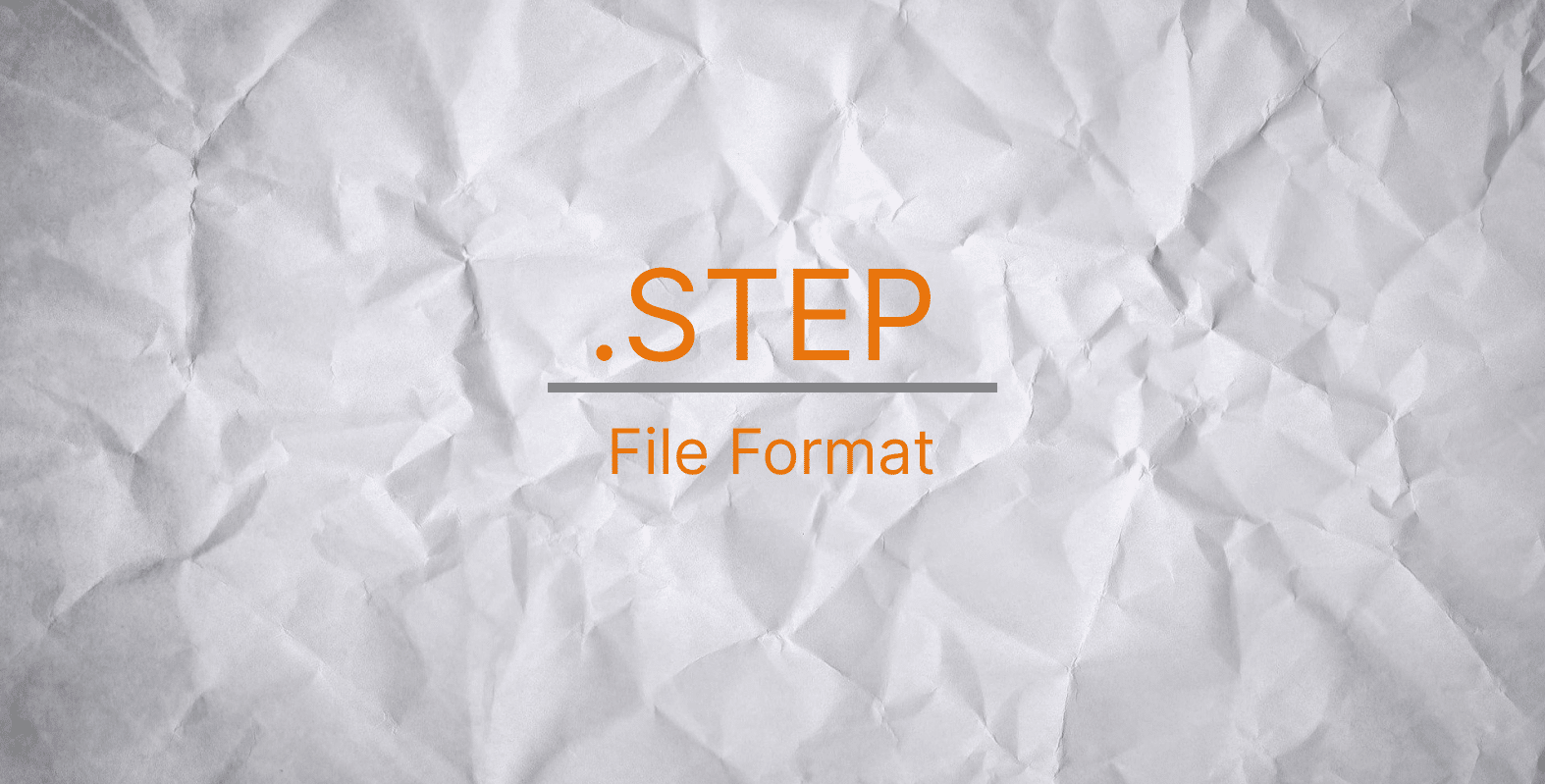

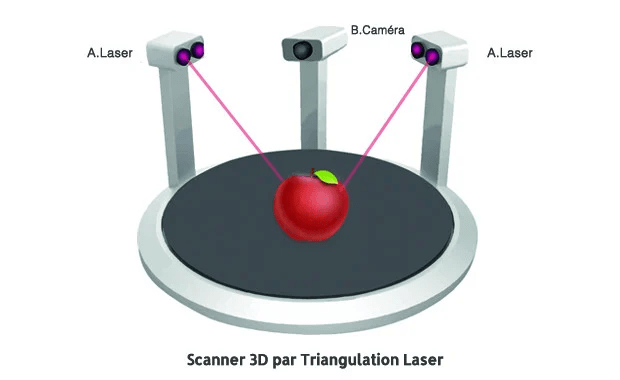

Laser triangulation 3D scanning technology

The triangulation method is used in three-dimensional laser scanning. The scanning device sends a laser beam to the object, and the camera captures the position of the laser contact point. The laser dot, the camera and the 3D scanner form a triangle. The “point cloud” obtained in three-dimensional scanning is connected by a grid of triangles, which serves as the basis for subsequent reverse engineering.

Photogrammetry 3D scanning technology

Photogrammetry is an easy way to scan reality. It is the most affordable and versatile way to get a three-dimensional model of an object or scene. Photogrammetry determines the shape, size and position of things from photographs.

In the first stage, a series of photos are taken using a conventional camera. The object is photographed from all sides. After that, the program finds defining matches on each image. There are several methods for obtaining such descriptors: SIFT, SURF, KAZE, AKAZE, ORB and BRISK.

Next, the program maps the descriptors to each other and turns them into a three-dimensional point cloud that describes the reconstructed object. Next, the program builds a depth map for each photo, where the distance is calculated from the camera to every pixel. Then the algorithm considers the average pixel value, and the mesh is textured.

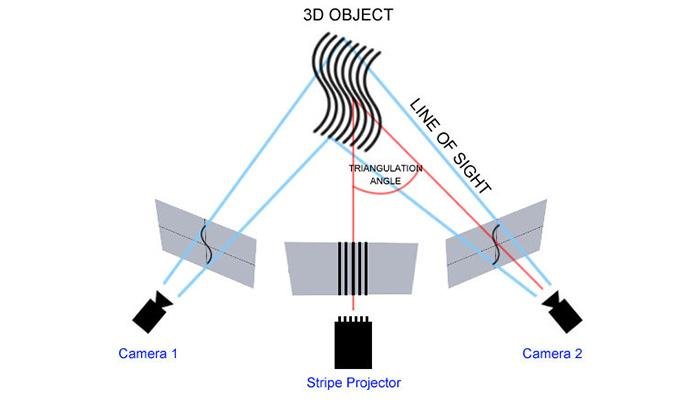

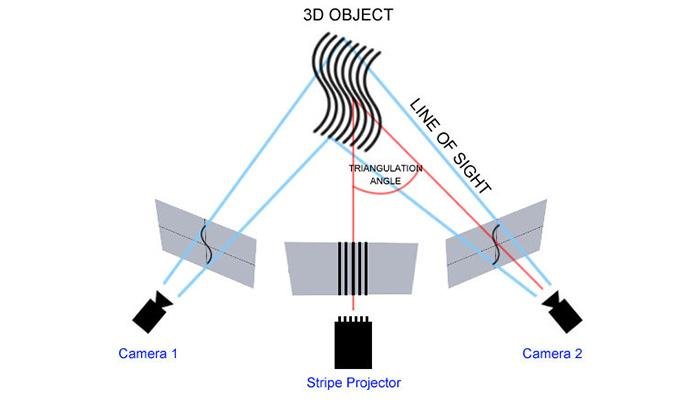

Structured light 3D scanning technology

Structured light projection represents the development of a technique based on lasers. A light grid is projected onto the object, and cameras record the distortion of the object’s surface. This makes it possible to shoot all the necessary parts simultaneously.

3D scanners are becoming more widespread with the digitalization of production and measurement processes. Projection strip technology is ideal for high-precision scanning at short distances and recognising small elements.

The wide projection area allows such scanners to register more than 2 million measurements per second with an accuracy of several microns. In addition, the high output resolution of the three-dimensional grid will enable you to reproduce the object’s geometry. The possibilities of 3D structured light scanning largely depend on the following aspects:

- light source (white or blue light; DLP, LCD or laser);

- pattern type (stripes, grids, etc.);

- characteristics and configuration of cameras;

- software.

Different combinations of these factors provide a wide range of opportunities for solving various tasks.

Laser pulse 3D scanner

In pulse 3D scanners, a method for determining distances is implemented based on the exact time it takes for a pulse to go to the target and back. Since this method uses a light pulse for direct distance measurement, the main advantage of pulse scanners is the range of sizes performed, which is provided by sufficiently high laser power. But remember that lasers can be harmful to the eyes.

The values of the horizontal and vertical angles of rotation of the laser head are recorded to determine the spatial position of the point. The accuracy of measurements by pulse scanners can reach several millimeters, but it decreases with increasing distance to the object.

It is essential to understand that the maximum range of measurement by scanners, given in various advertising booklets and descriptions, is calculated when the laser beam is reflected from a surface with a high reflection coefficient.

However, in actual measurement conditions, the reflectivity coefficient of the surface of the scanned object is almost always lower. Therefore, the maximum measurement range is also reduced.

Applications of 3D scanners

3D scanning is used in the following areas:

Architecture and construction. The capabilities of three-dimensional modeling, 3D printing and rapid prototyping have revolutionized layout design, elevating the manual creation of layouts to the level of expensive art.

3D printers are widely used to create various forms and prototype visualizations. The time it takes to create a design or a conceptual prototype model ranges from several minutes to several hours.

Automotive industry. It is difficult to overestimate the possibilities of using 3D printing in the automotive industry. Since it allows you to simulate details of any complexity, the 3D printing process takes only a few hours, reducing the design time of finished products. As a result, it is now easy to make any bold idea for a car a reality.

Surveying. 3D printers allow you to print high-quality local, urban and soil maps in hours at a low cost. The technology will fundamentally improve the use of GIS data for communication and allow critical elements to be analyzed with fast, inexpensive and easily reproducible 3D models.

Engineering. 3D technologies make it possible to produce parts of almost any shape and geometric complexity without traditional machines, tools and accessories, providing a sharp reduction in the time of the entire product creation cycle, from the idea to the product’s entry into the market.

It is often necessary to make adjustments and correct errors at the design stage, and it helps if you can 3D print the part yourself. If you order parts from third-party companies, the time and costs can be significant.

Design and advertising. 3D printers allow you to make trial layouts of packaging, vials and bottles of the original shape. Prototypes can be colored, including all design elements: labels, barcodes and brand names. You can demonstrate ready-made packaging models to the customer before mass production launches.

And this is just the tip of the iceberg of 3D printing capabilities. Almost every day, there are new opportunities for using this technology. 3D printing is increasingly entering our daily life, improving and making it more accessible.

Medicine. 3D printing is gaining more and more popularity in medicine, which opens up new horizons and helps save lives.

Preoperative planning helps improve the accuracy of surgical operations and reduces the risks and costs associated with the “blind” method of preparation for surgery. This can include producing 3D models, layouts, and implants to be used during surgery.

Molecular modeling — the production of full-color models of molecules with a high degree of detail — helps in research institutes whose activities are devoted to developing medicines.

Training. You can transform complex two-dimensional images into visual 3D models that facilitate the understanding of anatomy by medical students. In addition, they are handy for making it simpler to read results from the computer and magnetic resonance imaging.

Conclusion

3D scanning is a process that allows you to translate data about a physical object into digital form. The final information will be presented as a file in STL and other formats. You can convert these formats to any other format used in 3D modeling. 3D scanning of small objects is carried out using special equipment and a turntable, allowing you to scan the object from all sides evenly.

With the help of 3D scanning of small objects, you can digitize even the most minor thing. For example, it can be a piece of jewelry, a small part of a car or any other equipment, a souvenir, etc. There are no severe limitations for 3D scanning, especially when it comes to small objects. The only thing is that difficulties may arise with black objects and objects with shiny surfaces. For this purpose, special matting sprays are used.

At CyberFox, you can order 3D scanning of small objects. With our help, you can get an exact three-dimensional copy of a small thing of any geometry.

Determining the possibility of 3D scanning depends on the specific conditions. However, our specialists have extensive experience in this field and can find a solution for even the most challenging task.

we reply in 1 day